Plywood vs. Blockboards: Which Is Best for Residential & Commercial Construction?

Share

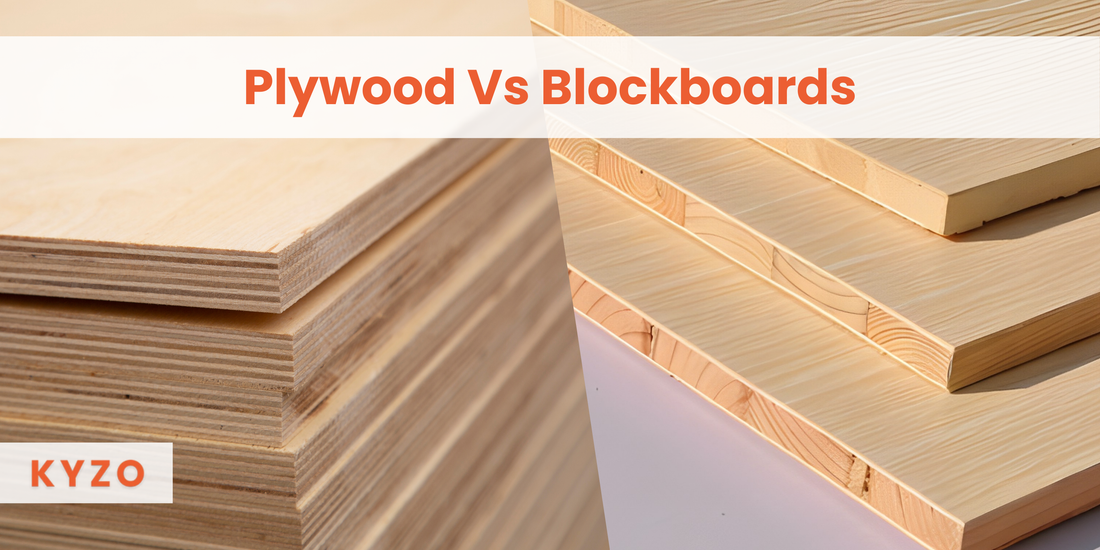

Building materials' right selection is dependent on the place which you are going to a construct. There are common opponents that happen the most times when choosing the materials for construction, furniture, or home products, that is, plywood and blockboards. Both materials have unique characteristics, the one on which they are usually used, and the one on which they are utilized the most, so they are the most common materials in construction whether you are building a house or a commercial house. However, discussing the essential differences between plywood and blockboards will aid in making a well-informed decision.

What is Plywood?

Plywood is a type of geared (e.g. the artificial bonding of the sheets of thin wood veneer under high pressure) wood, which is made of layers of thin sheets, and after that, these are glued together under high pressure. Plywood veneer sheets are laid out in alternating directions that improve the strength and durability of the material. This technology helps to balance plywood to prevent warping and splitting if possible.

Explore the kyzo’s plywood collection here.

What is a Blockboard?

Blockboard is another engineered wood type, which is the main difference that they are made by mounting the inner part that consists of blocks of softwood, then the outer layer of plywood or hardwood is put on top of the sample. This way of construction reinforces the blockboard with a hard molten core and a hard and thick outer part. They are mainly used in places with high strength and durability, and need them and make them a better option than plywood which is not suitable for this purpose. Blockboards are mostly utilized for doors, panelling, and large furniture to a greater extent in commercial spaces or areas where heavy load is to be carried. The strongest point about the blockboards compared to the others are that they are the most powerful of all and can bear the most weight.

Plywood vs. Blockboards: Key Differences

The prioritization of the specific differences that are unique to a certain application should be the most important factor when choosing between plywood and blockboards. Let's consider the most notable of these differences:

| Feature | Plywood | Blockboards |

| Construction Method | Thin layers of veneer glued together in alternating grain patterns. | Core of softwood blocks sandwiched between layers of plywood/hardwood. |

| Strength & Durability | Moderate strength, less durable compared to blockboards. | Stronger, more durable, and capable of supporting heavy loads. |

| Weight | Lighter compared to blockboards. | Heavier due to the solid core structure. |

| Cost | Generally more affordable. | More expensive due to the construction method. |

| Surface Finish | Smooth and uniform finish, ideal for veneering. | May have a slightly uneven surface, but can be veneered or laminated. |

| Flexibility | More flexible, easier to bend or shape. | Less flexible, better for straight applications. |

Looking for Khidki Gold MR Plywood

CenturyPly Bond 710 BWP Plywood

KHIDKI Gold MR Plywood

Greenply Absolute MR Plywood

Greenply Absolute BWP Plywood

Greenply Club Flexiply BWP

Greenply Platinum BWP Fire Retardent Plywood

GreenPly Green MR

GreenPly Green GOLD BWP 710

GreenPly Green Ecotec BWP 710

GreenPly Ecotec MR

CenturyPly Architect Plywood

CenturyPly Club Prime BWP Plywood

CenturyPly WIN MR Plywood

CenturyPly Sainik 710 BWP Plywood

CenturyPly Sainik MR Plywood

KHIDKI Prime Plus Calibrated MR Plywood

KHIDKI Flexi Plywood (Imported) - 8ft x 4ft

KHIDKI Gold Plus Calibrated BWP 710 Plywood

KHIDKI Silver Plus Calibrated BWP 710 Plywood

KHIDKI Silver Calibrated MR Plywood (Neem Face)

Strength and Durability

It is a general fact to say that Blockboards are stronger and more durable than plywood normally. A Blockboard's solid wood block core gives it a better ability to bear heavy loads, and it is stronger than plywood. The strength of plywood, however, depends on the sample and the number of layers. Plywood is very strong and it is being used in most houses and some commercial buildings, but it won't be a product that is strong enough for heavy-duty use compared to blockboards.

Weight

Although blockboards are heavier than plywood due to the solid core, they can be an advantage and a disadvantage as well. This depends on the use of the material. Thus, if you are looking for a durable material for a heavy-duty application, blockboards are the right choice; even so, keep in mind that the added weight can be a key factor in some projects. On the contrary, the light weight of plywood fastens the handling and installing process, especially if we talk about residential construction.

Cost

Although blockboards are heavier than plywood due to the solid core, they can be an advantage and a disadvantage as well. This depends on the use of the material. Thus, if you are looking for a durable material for a heavy-duty application, blockboards are the right choice; even so, keep in mind that the added weight can be a key factor in some projects. On the contrary, the light weight of plywood facilitates the handling and installation process, especially if we talk about residential construction.

Surface Finish

On one hand, plywood and blockboards are both with the facades of the simplest kind, usable not only in the interiors but also exteriors. While plywood generally appears to have a smoother surface that is mostly utilized in applications such as furniture and cabinetry, blockboard, however, is not as smooth as plywood. Softwood might result in uneven surface boarding, yet it can help by either veneering or laminating to get a smooth finish.

Flexibility and Versatility

Plywood is essentially a structure that is thin and highly durable, which could be stronger and more durable if it is made of fewer layers. Unfortunately, these distinctive features also make it a perfect choice for curved or other composite work. The blockboards that are made of wood are, on the other hand, not flexible; they are mainly used for heavy-duty and straight elements.

You can also look at Khidki Silver Plus Calibrated BWR Plywood

Applications of Plywood and Blockboards

Both marine plywood and blockboard are suitable for a variety of uses and can work wonders, but each is suitable for the specific needs of the project in question. Here are some of the typical uses of each material:

Applications of Plywood:

| Application | Uses of Plywood |

| Furniture Making | Cabinets, shelves, tables, chairs, etc. |

| Flooring & Roofing | Subflooring and roofing for both residential and commercial construction. |

| Walls & Partitions | Partition walls and paneling. |

| Cabinetry | Kitchen and bathroom cabinets. |

Applications of Blockboards:

| Application | Uses of Blockboards |

| Doors & Windows | Ideal for strong, durable doors and windows. |

| Furniture | Heavy-duty furniture like desks, wardrobes, and large tables. |

| Panelling | Wall panelling, especially in commercial spaces. |

| Heavy-duty Construction | Used where additional strength is required. |

Looking for Khidki Blockboard

Which is Better for Residential and Commercial Construction?

Now that we have discussed the difference between plywood and blockboards, let’s look at which material is better suited for residential and commercial construction.

Residential Construction:

In residential construction, the most common plywood is the preferred choice as it is lightweight, versatile, and less expensive. It is suitable for all types of furniture, flooring, walls, and cabinets. On the contrary, blockboards may be chosen in the circumstance that more strength is needed, as they are the best material for doors or large furniture pieces.

Commercial Construction:

In commercial areas, where the main things to have are durability and strength, a better choice will be blockboards for heavy-duty furniture, doors, and panelling. These are also the ones that should be chosen in applications where weight-bearing capacity is a concern. However, plywood is still widely used in commercial applications as it is affordable and transportation is not a problem at the same time.

Conclusion: Plywood vs. Blockboards – Which Should You Choose?

The choice of plywood or blockboards is very much dependent on the specific needs of your construction job. For housing, plywood is usually the better alternative due to its lighter weight, bending ability, and lower cost. If your plan needs to have extra strength and durability, think about large furniture or other structural applications, and blockboards are the better choice then. Finally, distinguishing the pros and cons of plywood and blockboards, as well as their areas of use, will enable you to choose the most appropriate one for your construction or furniture project. Whether you are renovating your house or you are engaged in a commercial construction project, both plywood and blockboards can be used to furnish high-quality and durable materials. Carefully assess your needs, and find the material that suits your budget and project requirements the most. You will gauge and comprehend the differences, strengths, and applications of both plywood and blockboards; thus, you can logically decide on the best material for your project.

FAQs

Q1. Which is stronger: plywood or blockboard?

Ans. Blockboard is stronger due to its solid core, making it ideal for heavy-duty applications.

Q2. Is plywood more expensive than blockboard?

Ans. No, plywood is generally more affordable, while blockboards cost more due to their construction method.

Q3. Which is better for furniture: plywood or blockboard?

Ans. Plywood is better for lightweight and flexible designs, while blockboards are preferred for heavy-duty furniture.

Q4. Does the blockboard warp easily?

Ans. No, blockboards are less prone to warping than plywood, making them ideal for doors and large panels.

Q5. Can plywood be used for doors?

Ans. While plywood can be used, blockboard is a better door choice due to its strength and durability.

Q6. Which is more suitable for commercial construction?

Ans. Blockboards are preferred in commercial spaces where strength and durability are essential.