Edge Banding 101 – How to Achieve a Flawless Finish

Share

In the world of modern interior design, it's the small details that make a big difference. One such detail is edge banding, a technique that ensures your furniture and fixtures have a clean, polished, and professional appearance. Whether you're working on kitchen cabinets, office furniture, or custom home projects, edge banding plays a vital role in enhancing the aesthetic of your design while also ensuring durability.

What is Edge Banding?

Edge banding refers to the process of applying a thin strip of material (usually made of PVC, wood veneer, or melamine) to the exposed edges of furniture or panels made from engineered wood products like plywood, MDF, or particle board. This not only improves the overall look but also protects the raw edges from moisture, wear, and tear.

Why is Edge Banding Important?

In addition to enhancing the visual appeal, edge banding offers several benefits:

- Protection: It protects the core material from damage, such as chipping and peeling.

- Durability: Prevents the edges from absorbing moisture, which can cause swelling or deterioration.

- Aesthetic Appeal: Provides a seamless and consistent finish, making your furniture look sleek and polished.

Now that we understand the importance, let's dive into how you can select the right edge band shade and apply it flawlessly.

1. Selecting the Right Edge Band Shade

Choosing the right edge band color and finish is key to achieving a cohesive and sophisticated look for your design. Here are some tips on selecting the perfect match for your laminate or wood surface:

Match with Laminate for a Seamless Look

When selecting an edge band, the first step is to match it with the laminate color or texture. The goal is to ensure that the edges blend in seamlessly, creating an illusion of a continuous surface.

-

Solid Colors: If you’re using a solid-colored laminate (such as white, black, or grey), opt for an edge band in the same color or a complementary shade. For a minimalistic, modern look, matching the edge band with the laminate creates a sleek and understated design.

-

Wood Veneer Laminate: For wooden laminates, the edge band should either match the grain pattern and color of the laminate or complement it with a similar wood shade. If you want to add contrast, you could opt for a slightly darker or lighter edge band for an added dimension.

Consider Texture for Realism

Texture is another key factor in choosing the right edge band. For instance, if your laminate has a textured finish, it’s important to match that texture with your edge band for a more authentic, cohesive appearance. There are edge bands available that mimic the texture of the laminate, such as embossed or brushed finishes, which provide a more realistic wood-like appearance.

Play with Contrast (When Appropriate)

In some designs, a contrasting edge band can add a touch of flair and sophistication. For example, pairing a light-colored laminate with a dark edge band can add drama to the design. However, use this technique sparingly, as it’s more suitable for modern or contemporary interiors, where high contrast can stand out.

2. Applying Edge Banding for a Flawless Finish

Once you've selected the right edge band, it’s time to apply it. Here’s a step-by-step guide on how to do it for the best results:

Step 1: Measure and Cut the Edge Band

Before application, measure the length of the edge where the banding will be applied. Use a sharp utility knife or scissors to cut the edge band to the required length. It’s essential to cut the banding a little longer than the edge itself to allow for trimming later.

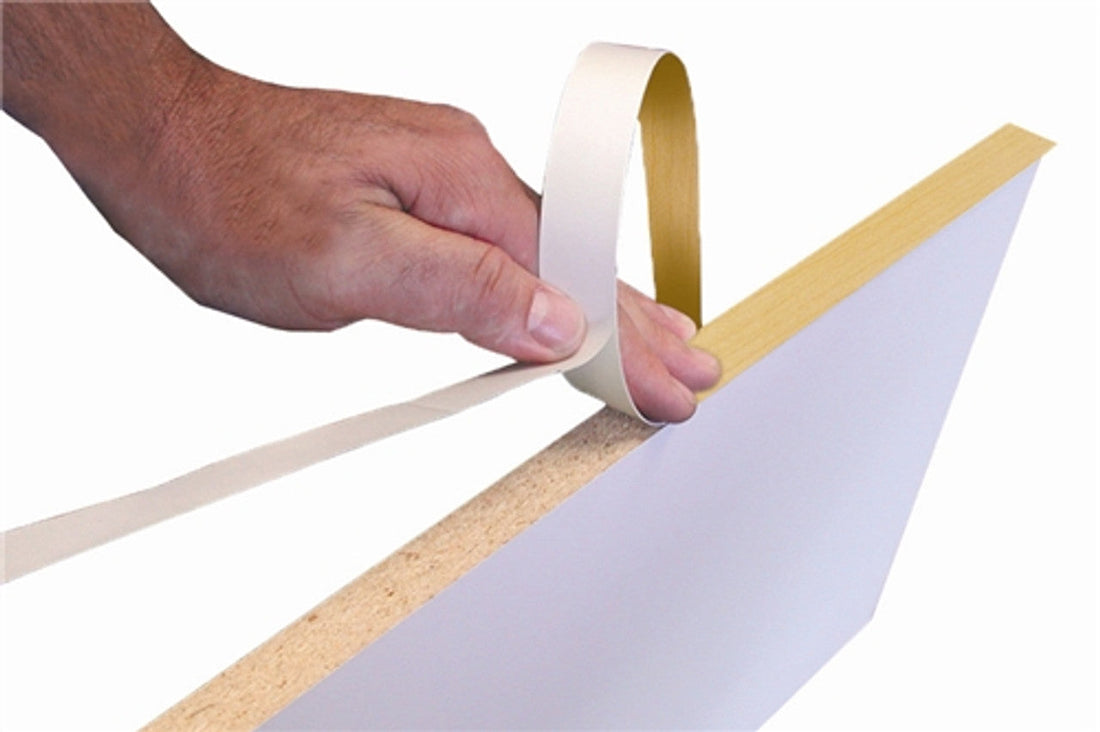

Step 2: Apply the Edge Banding

Edge banding can be applied using two methods: manual or machine application. In a professional setting, edge banding machines, commonly found in modular factories, provide a precise and quick way to apply edge bands. These machines heat the adhesive on the edge band, ensuring that the band adheres firmly to the panel without wrinkles or air pockets.

-

Manual Application: For DIYers, a hot glue gun or adhesive tape can be used. Carefully apply the adhesive to the edge of the panel and then press the edge band into place.

-

Machine Application: In modular factories, edge banding machines are highly efficient and provide a flawless finish. These machines use heat and pressure to apply the edge band with precision, ensuring that the band is firmly bonded to the panel. The use of automated machines also allows for a smooth, consistent application that enhances the overall finish.

Step 3: Trim and Smooth the Edges

Once the edge banding is applied, use a sharp trimming tool to cut any excess banding along the edges. Be careful not to damage the surface of the laminate while trimming. After trimming, use sandpaper or a file to smooth out any rough edges and ensure the banding blends smoothly with the rest of the panel.

Step 4: Final Touch

If necessary, apply a small amount of adhesive to any loose edges and reapply pressure. Once the banding is secure and smooth, you can proceed with additional finishing touches, such as polishing or cleaning the surface to remove any adhesive residues.

3. Using Edge Banding Machines for Precision

Edge banding machines in modular factories are a game-changer for achieving a flawless finish. These machines are equipped with advanced features that not only apply the edge banding efficiently but also trim and smooth the edges automatically, saving time and effort.

For large-scale manufacturing or projects that require high precision, edge banding machines offer unmatched consistency and quality.

Conclusion

Edge banding is a crucial step in modern interior design that elevates the look and durability of furniture and fixtures. By carefully selecting the right edge band shade to match your laminate and applying it with precision, you can ensure a flawless finish that enhances the aesthetic of your design. Whether you’re applying edge banding manually or using the advanced technology of edge banding machines in modular factories, the key is to focus on detail and precision for the best results.

At Kyzo, we offer a variety of edge banding materials that complement our high-quality plywood and laminates. Whether you’re working on a residential project or a commercial space, we’re here to provide the tools and materials you need for a professional, flawless finish.